Consider Prototyping

There are many reasons to consider a prototype before diving into the manufacturing process. At Apex we’ve been providing prototypes to our customers for years and have firsthand experience of the advantages. A prototype allows for testing and evaluating numerous attributes of the product before committing extensive resources to manufacture. Benefits include product improvement, overall cost savings, and increased customer satisfaction. Let’s explore these advantages further.

Product Improvement

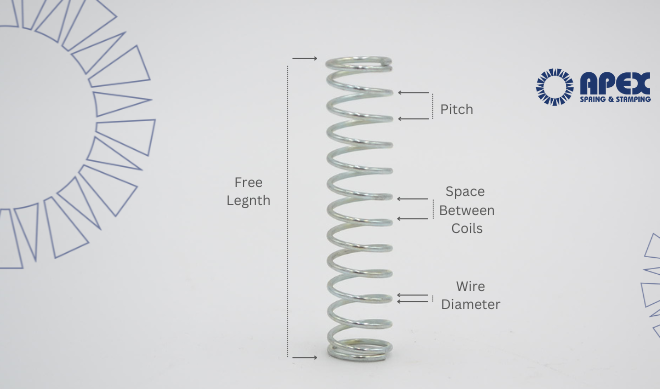

Let’s consider spring manufacturing. We develop a high volume of prototypes of springs. Especially those that go into an assembly. This is because of the challenge involved in determining the requirements of a spring for use in an assembly. Prototyping allows customers to refine the design so that the exact requirements are met before the start of production.

Prototyping allows us to dial in specific load, material, plating requirements, or specific tolerances. Then the design can be tweaked if necessary. Those improvements lead to cost saving, more efficient and effective manufacturing, and overall a better end product.

Cost Savings

In addition to finalizing the design of your spring prototyping will bring you cost savings in multiple ways. This includes avoiding any changes or tweaks to the product during production. Changing products in production can be very costly. Prototyping provides the opportunity for multiple changes and runs at a much lower cost. It is more cost effective to have multiple prototype runs then one change the production stage.

Another example of cost savings is in the product design including springs function. When our engineers assist with the prototype design it allows us to give the customer feedback after seeing the part assembled or functioning. With years of experience and expertise, we are able to anticipate design needs in order for the parts to function properly.

There is also a cost savings opportunity in the connection from design, to prototype, to manufacturing. Because of our experience and expertise we are able to provide cost saving at every stage of the process. We can use the prototype stage to work through ways to design and manufacture the product more effectively and efficiently. Whether this be suggesting a more cost effective plating choice at the quoting change or suggesting an efficient way to solve a problem during the prototype stage. Apex is here to save you time and money.

Customer Satisfaction

In addition to the technical benefits to prototyping, it’s important to always consider overall customer satisfaction. Prototyping directly impacts the customers satisfaction of their final product. This includes confidence in the product before production, overall cost saving, and the quality and function of the final product. All can be significantly higher with prototyping.

Even so, one concern we hear from customers is about the time required with prototyping. We understand the strain of trying to get everything completed before production starts. That is why fast turnaround is one of our core advantages, and that includes prototyping. Apex prices ourselves with our ability to meet your due dates and keep you on schedule!

Finally, let’s not forget the expanded knowledge and peace of mind that is gained during the prototyping process. This includes tangible details about the product, function or manufacturing process. All of these are reasons we encourage our customers to prototype. We know it will bring you increased satisfaction when it comes to launching your part into production.

How can we help?

Apex is ready to serve your needs for each individual project. Consider allowing us to provide a prototype so that you can go into production with confidence. Can our team help you with your next project?

| Contact Us | Request A Quote |