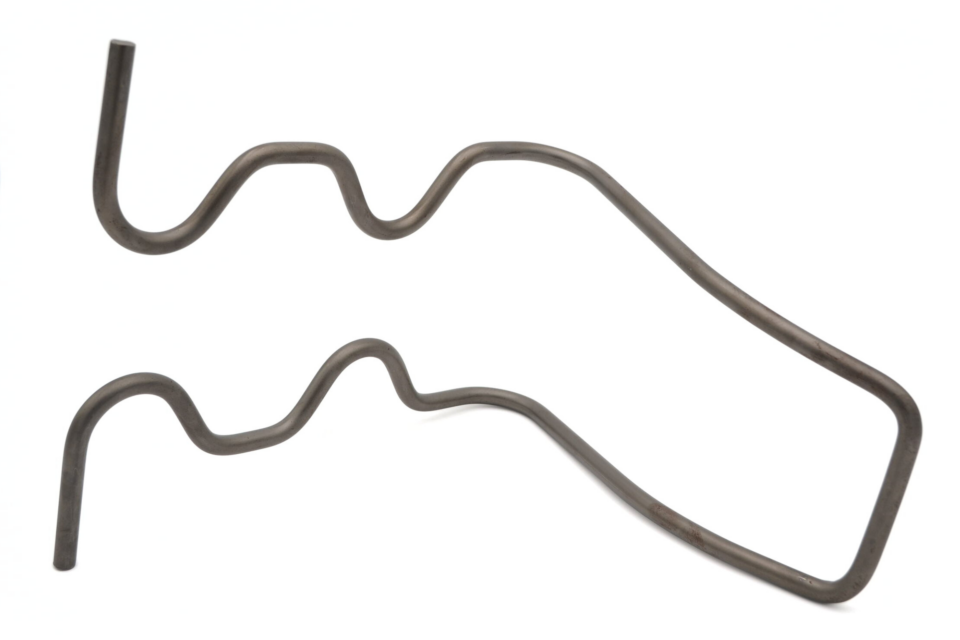

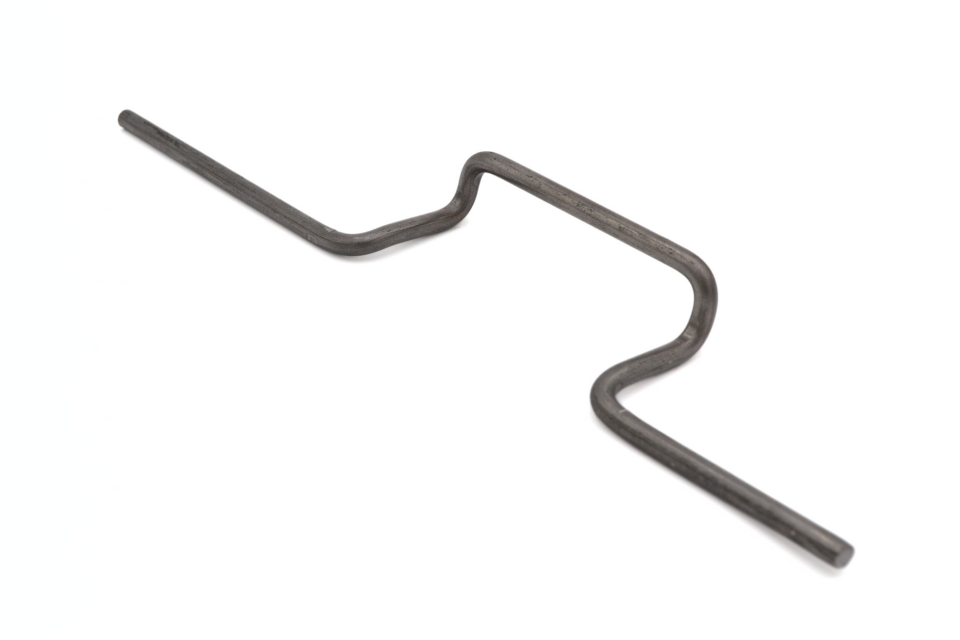

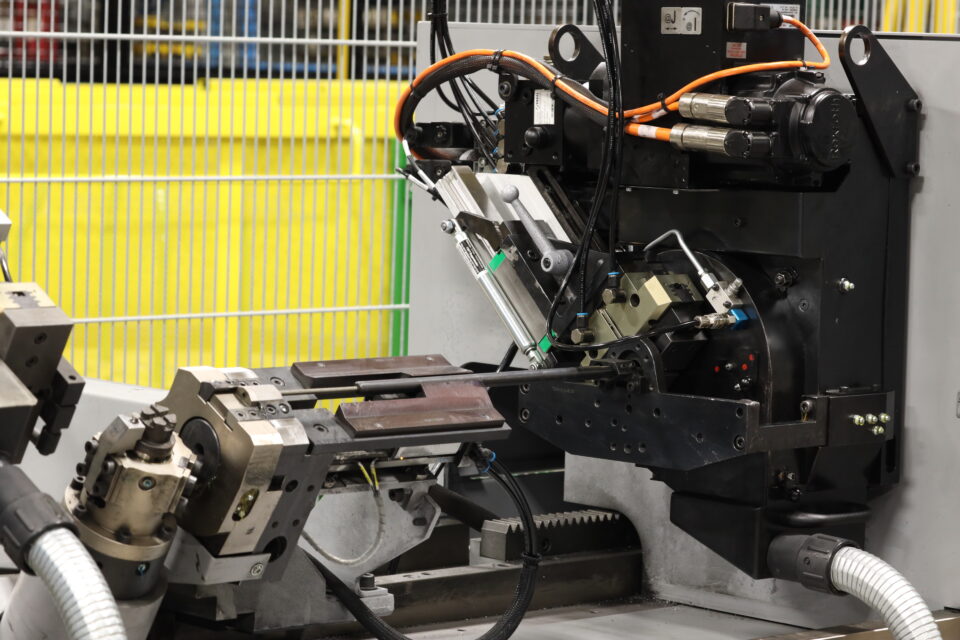

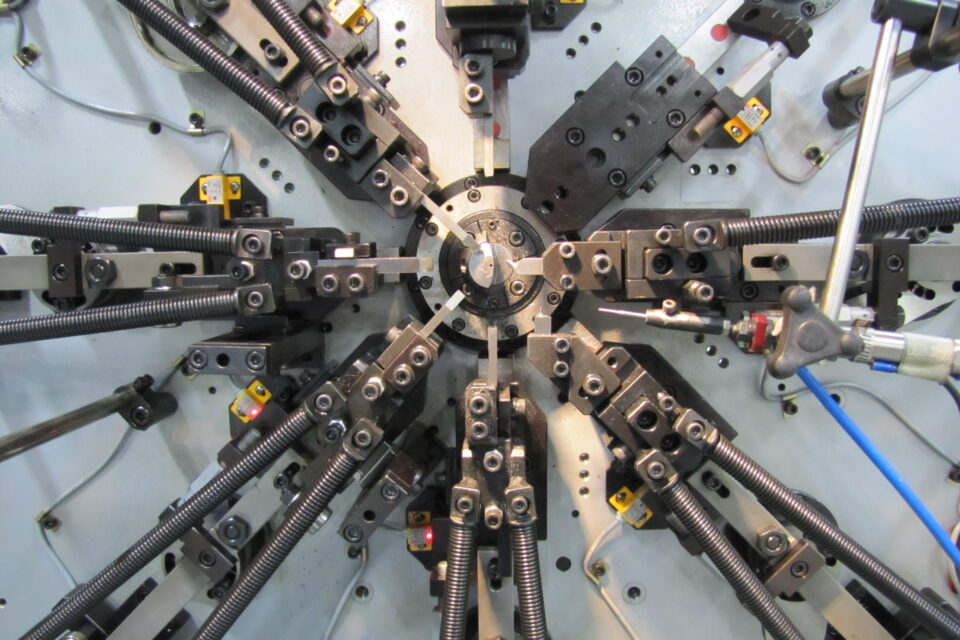

Apex Spring & Stamping provides highly precision wireforms customized to the needs of our customers. From low to high volume run capabilities we are outfitted with a variety of machines and systems to manufacture a fully customized product. Apex engineering team can also provide developmental support through engineering and prototyping.

Capabilities & Specifications

Common Materials

- Music Wire

- Low or High Carbon Material

- Chrome Silicon

- Stainless Steel (302,316,17-7)

- Material range:.070” to 0.630” diameter

Post Processing Offerings

- Stress relieving

- Protective Coatings

- Passivating

Wire Size Range

- Wire sizes low carbon .25mm – 16.0mm (.010” – .630”)

- Wire sizes high carbon, .25mm – 13.0mm (.010” – .512”)