In today’s competitive manufacturing environment, quality isn’t just something you check at the end — it’s built into every step of your process. At Apex, we’ve developed assembly practices that emphasize quality from start to finish. We understand that thorough quality control in assembly reduces defects, returns, and downstream costs is essential.

The following sections walk through why assembly quality matters, ways we ensure quality at Apex, and how this commitment leads to better outcomes for our customers.

Why Quality in Assembly Matters

Assembly may seem like just another step in bringing a product together — but getting it right impacts everything downstream.

- Defect reduction — A poorly assembled product rarely performs as intended. Ensuring quality prevents costly rework and returns.

- Customer satisfaction — Fewer defects mean higher confidence from your customers and stronger supplier relationships.

- Supply chain efficiency — High quality reduces interruptions, unplanned delays, and escalated logistics costs.

At Apex, we understand that assembly is part of a larger manufacturing ecosystem built around precision, consistency, and standards.

Ways We Ensure Quality in Every Assembly

Experienced People + Defined Processes

Human skill and process discipline are at the core of quality:

- Experts who understand components and tolerances — Our assembly team combines years of experience with formalized procedures, so each task is done right.

- Standard work and sequencing — Established steps ensure consistency across all assembly jobs, whether simple or complex. Protocols reduce variability and prevent mistakes before they happen.

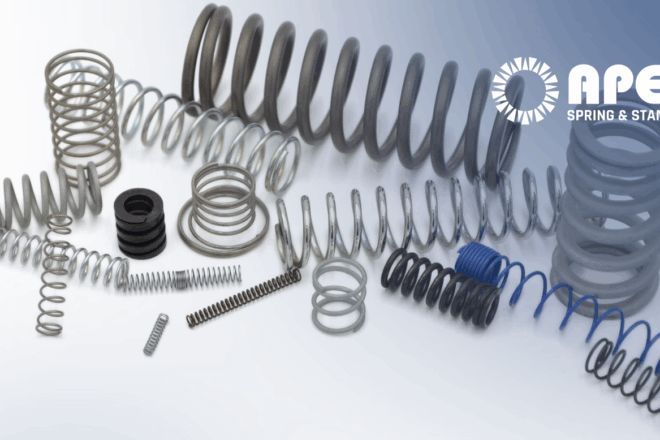

This human foundation is backed by decades of precision manufacturing at Apex — starting with springs and stampings and extending through full assemblies.

Tools and Capabilities That Support Quality

Good quality control relies on the right tools, equipment, and infrastructure. At Apex we utilize a variety of assembly equipment that promotes repeatability and precision:

- Torque guns to apply accurate, consistent torque to fasteners — crucial for maintaining joint integrity without over-tightening or under-tightening.

- Orbit riveters and presses to ensure uniform fastening and mechanical joining.

- Kitting machines that organize and verify components ahead of assembly — reducing setup errors and handling issues.

- And more… with a wide variety of tools and capabilities we can customize the process to the needs of each assembly.

These capabilities don’t just support assembly — they improve quality by reducing variables that lead to errors.

Inspection and Verification

Quality control isn’t just a final inspection — it happens throughout the assembly workflow. Some of the ways we ensure thorough verification include:

- In-Process Checks: Rather than waiting until the end of the line, quality checks occur at key stages. This includes dimension and fit checks, torque verification, and functional testing.

- Final Inspection and Testing: Every assembly that leaves our facility undergoes a final series of checks:

- Documentation and traceability so customers can see exactly what was measured, tested, and approved.

This layered approach ensures quality at every step.

Partnering With Engineering to Prevent Issues

A unique advantage at Apex is the close collaboration between our engineering and assembly teams. Before any assembly project begins, engineering support helps optimize designs to ensure assembly success — even under tight tolerances.

Our engineering services include:

- Assembly analysis and design for manufacturing — reducing part complexity and making products easier to assemble with fewer errors.

- Tolerance and stack-up evaluations to minimize fit issues on the line.

- Prototyping support — validating designs in real physical tests before full production starts.

By involving engineering early, we help prevent quality issues before they ever reach the assembly floor.

Benefits of Quality Control in Assembly

The benefits of this disciplined quality approach aren’t abstract — they translate directly into value for you:

- Fewer supplier complications — reducing the frequency and cost of dealing with defective returns.

- Lower total cost of ownership — investing in quality upstream saves money downstream.

- Reliable delivery performance — quality drives consistency, which supports accurate production planning.

- Stronger partnerships — quality builds trust between OEMs and their suppliers.

At Apex, we view quality and service as inseparable — which is why quality isn’t just a checkpoint, but a culture embedded into every assembly process.

Apex is Your Assembly Expert

Assembly quality control matters — not just while the parts are at our plant, but for every step in the process thereafter. Apex understands this, and therefore ensures that your assemblies meet the highest standards before they reach the next line, or the end customers.

Looking to improve your assembly quality or simplify your supply chain? Contact the team at Apex Spring & Stamping today — we’d love to talk to you!

| Contact Us | Request A Quote |