Suppliers who truly become an extension of your business by extending your capabilities are incredibly valuable. At Apex, we understand that value from both sides! With decades of experience in custom manufacturing, we are good at what we do and we know our products well. We also are dedicated to collaborating with engineers and purchasing agents to design, prototype, and produce components that keep projects moving forward.

Our process is built around partnership, efficiency, and quality. Here’s how working with Apex looks step by step:

Step 1: Start with a Conversation

Every project begins with a discussion — not a sales pitch.

- Our engineering team connects with yours to understand the application, requirements, and performance goals.

- Whether it’s a phone call, video meeting, or plant visit, our focus is on your challenges and your customer’s needs.

This early collaboration sets the foundation for a true custom manufacturing solution.

Step 2: Define Requirements Together

Before design starts, we dig into the details:

- End-use environment and performance expectations

- Strength, motion, and durability requirements

- Integration with plastic parts, assemblies, or other systems

We ask the right questions up front and listen carefully so we can deliver a solution that meets function, budget, and timeline — without requiring a finalized print.

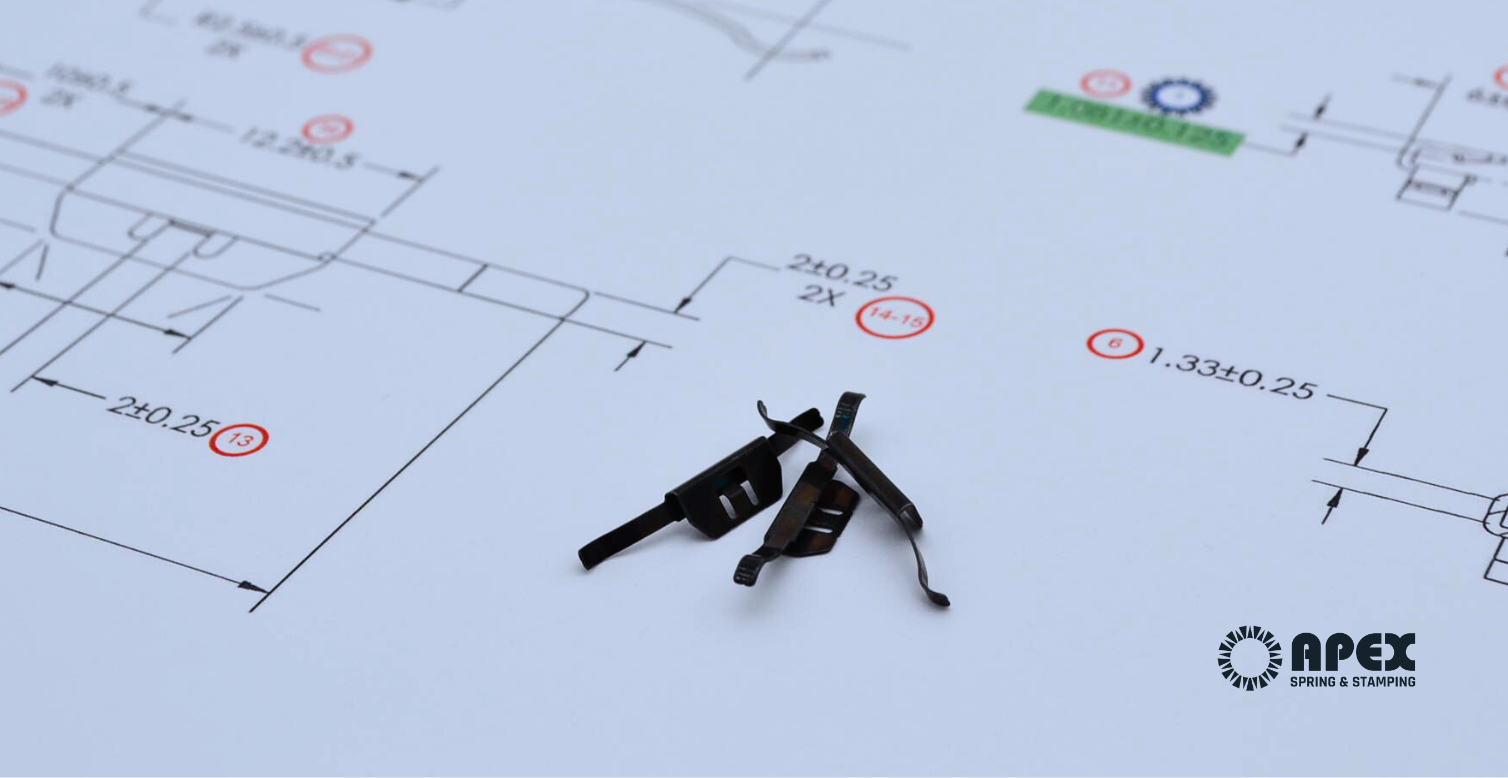

Step 3: Collaborative Design & Manufacturing

Once we understand the requirements, our engineers go to work:

- Designs are created in CAD software and tailored to your specifications.

- We recommend materials based on strength, fatigue, and cost-efficiency.

- Prototypes are built and tested in-house, with adjustments made quickly.

Our goal: get you a validated design faster, so you can move forward with confidence.

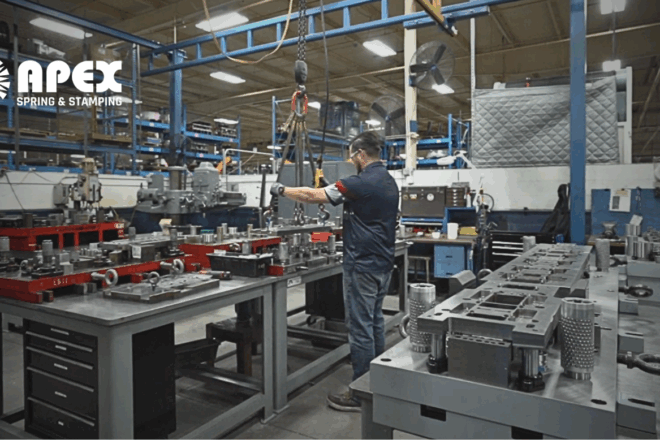

Step 4: In-House Tooling When Needed

One of Apex’s biggest advantages is our in-house tooling facility. Unlike many competitors, we build tools and manufacture in the same facility, saving you time and money:

- EDM and precision tooling are built on-site.

- Lead times are cut by weeks.

- Our toolmakers work hand-in-hand with engineers to ensure the design transitions smoothly into production.

This is where Apex’s investment in custom manufacturing pays off — shorter timelines, lower risk, greater value.

Step 5: Quality Planning & Validation

Before production begins, our cross-functional team runs through APQP (Advanced Product Quality Planning). This ensures:

- Every department can execute requirements with excellence

- FMEAs (Failure Mode Estimated Analysis) are conducted when needed

- PPAP (Part Production Approval Process) documentation is provided to meet customer standards

Parts go through first-piece approvals, retained samples, and rigorous stress/strength testing — all part of our built-in quality process.

Step 6: Precision Manufacturing & Ongoing Monitoring

When production kicks off, quality doesn’t take a back seat:

- Dedicated operators run the machines and perform SPC checks every two hours.

- Data is monitored for trends and CPK numbers to ensure parts remain in spec.

- If issues arise, machines are adjusted immediately — not after a run is finished.

With Apex, quality is not just a checkpoint, it’s a continuous process.

Step 7: Assembly & Custom Packaging (Optional)

Need more than a single component? Apex is fully equipped with:

- Multi-part assemblies (using Apex or customer-supplied parts)

- Specialized packaging such as kits or cell packs

- Final inspections to ensure assemblies meet performance requirements

This reduces your vendor count and simplifies your supply chain.

Step 8: On-Time Delivery

Finished parts are inspected, counted, and packaged with traceability in mind. We align production with your delivery schedules, so you get the parts you need — when you need them.

Why Engineers & Buyers Trust Apex

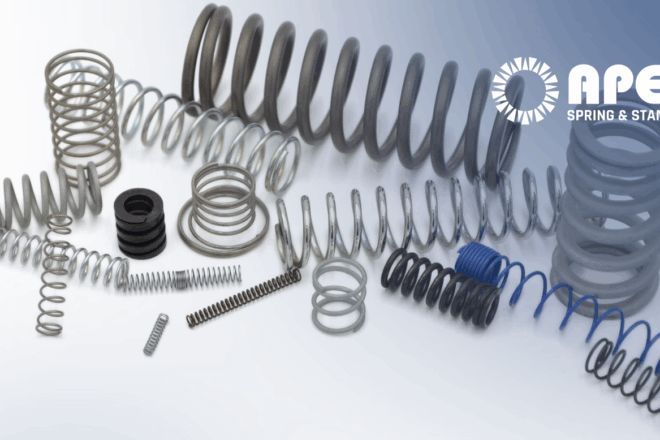

- Expertise in custom manufacturing springs, stampings, and wire forms

- In-house tooling for faster lead times and better control

- Rigor in APQP, FMEA, and PPAP processes

- Transparent communication from concept through delivery

- Flexible assembly and packaging options

Let Us Build Your Next Solution

Whether your design requires motion or precision components, Apex Spring & Stamping delivers the custom manufacturing expertise you need. From concept to production, we help you shorten timelines, reduce risk, and deliver better results to your customers.

Start the conversation with our engineering team today.

| Contact Us | Request A Quote |