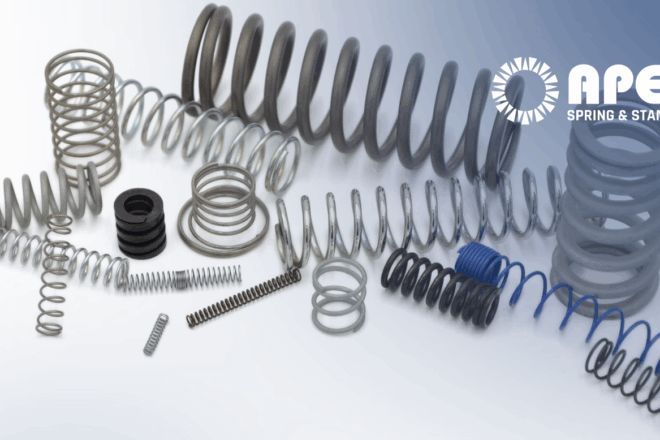

Compression springs are very versatile mechanical components, playing a crucial role in countless applications across industries. From everyday household items to high-tech aerospace systems, these springs are designed to store energy and absorb force, making them indispensable in modern engineering. Below, we explore the wide range of uses for compression springs, delve into the design factors like materials and key elements, and highlight their advantages.

What Are Compression Springs?

Compression springs are open-coil helical springs designed to resist compressive forces. When a load is applied, they compress to store potential energy, releasing it when the force is removed. Their simplicity and effectiveness make them a fundamental choice in mechanical systems.

Common Uses of Compression Springs

Compression springs are widely used in many applications. Below is a list of some of the most common. But really, the opportunities for compression springs are boundless!

- Automotive Industry

- Suspension systems

- Valve assemblies

- Brake mechanisms

- Engine Controls

- Aerospace and Defense

- Landing gear systems

- Missile and rocket assemblies

- Medical Devices

- Syringes and pumps

- Prosthetics and implants

- Electronics

- Battery compartments

- Switches and connectors

- Industrial Machinery

- Actuators, seals, and vibration dampening components

- Conveyor belts and pressing systems

- Milling and Drilling Equipment

- Precision Instruments

- Hand Tools

- Consumer Products

- Door locks, mattresses

- Toys and household appliances

- Staplers, notebooks, and pens

This list is just a small sampling of the thousands of uses that have been discovered for compression springs. With new developments, innovations, and inventions come new applications for compression springs. How will they be used next?

Key Design Factors for Compression Springs

To optimize a compression spring for a specific application, manufacturers must consider several design factors:

1. Material Selection

The choice of material significantly impacts the spring’s performance, durability, and corrosion resistance. Common materials include:

- Carbon Steel: Economical and suitable for general use.

- Stainless Steel: Offers excellent corrosion resistance, ideal for marine and medical environments.

- Alloy Steel: High strength and fatigue resistance for heavy-duty applications.

- Exotic Alloys (e.g., Inconel, Titanium): For high-temperature or specialty applications in aerospace or medical fields.

2. Design Elements

Application and use drive many elements of the design of a spring. The following highlights some of those key elements that are considered:

- Wire Diameter: Determines the spring’s load capacity and deflection.

- Coil Diameter: Influences the spring’s flexibility and energy storage.

- Spring Rate (k): The force required to compress the spring by a unit distance.

- Ends Configuration: Closed, open, or ground ends ensure stability and compatibility with mating components.

- Number of Active Coils: Affects the spring’s deflection and stress distribution.

3. Environmental Considerations

Springs operating in harsh environments require special coatings or materials to resist corrosion, extreme temperatures, or wear. Surface treatments like plating, powder coating, or shot peening can enhance their performance.

Advantages of Compression Springs

Compression springs offer numerous benefits, making them a preferred choice in engineering designs. Below are some of those advantages:

- Versatility: Applicable in a wide range of industries and systems.

- Energy Efficiency: Simple design ensures effective energy storage and release.

- Compactness: They provide high functionality within a small space.

- Durability: High-quality materials and proper design lead to long service life.

- Customizability: Springs can be tailored to meet precise load, size, and environmental needs.

- Cost-Effectiveness: Economical to produce, especially in bulk, and require minimal maintenance.

Apex Can Help!

Compression springs are more than just coiled wires; they are precision-engineered components that drive innovation in countless industries. By understanding the specific design factors manufacturers can optimize these springs for any application.

At Apex, we specialize in creating high-quality compression springs tailored to your needs. Whether you’re designing automotive components, medical devices, industrial machinery, or just about anything else, we have the expertise and manufacturing capabilities to deliver reliable solutions.

Contact us today to learn how Apex can support your spring and stamping needs!

| Contact Us | Request A Quote |