Apex Quality Standards

Quality is often only viewed by customers as PPM (parts per million). And often measured by manufacturers by the total number of quality complaints. At Apex, we strive to eliminate quality issues from the start. We do this through a variety of standards, testing, and measuring to achieve our customers a quality part. Our continued commitment is to meet the rigorous standards set forth by our certification in IATF -16949 (an international standard for the automotive industry). This helps us to produce a quality part expected with every order. Whether it’s an automotive, office, consumer product, or recreational customer, our standards are the same.

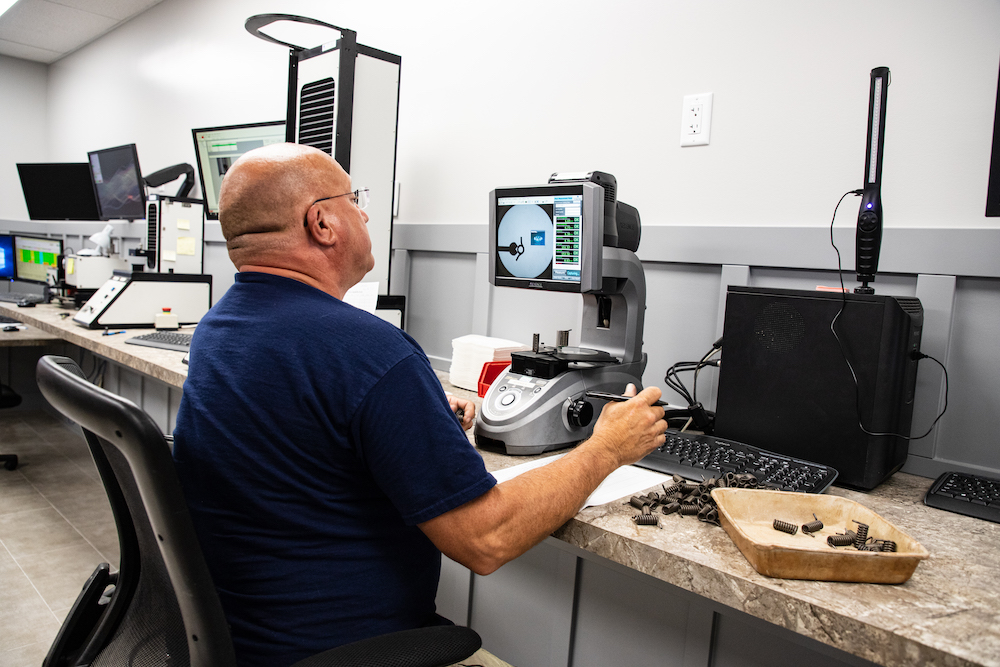

How We Use CMM

All our Apex team members are trained to operate and utilize a CMM (Coordinating Measuring Machine). But, in effort to to meet our high standards, we employ a quality team of 6 members. Combined they have over 90 years of quality experience. They perform tests, collect data, and troubleshoot when challenges arise. We use an array of highly sophisticated pieces of equipment to meet the demands of our customer’s parts:

- 3 CMM machines (located in spring and stamping production areas for quick access for our machine operators)

- Keyence Blue Light Scanner

- 8 Keyence Instant Measurement machines,

- 2 Starrett Digital Comparators,

- 4 Torsion Load Testers, 2 Compression Load testers and a

- 6-foot pair of Carbon Fiber Calipers

How We Process Data

So, what do we do with all this data? When an operator measures a part on our CMM or Keyence, the data automatically goes to the database. Whether it’s a customer critical or an Apex defined critical, all the data goes into our Infinity QS system to provide ongoing and instant feedback. Do you want to know the Cpk (process capability) of a specific part ran in 2013? Yes, we can do that. Do you want that part compared to the same part that ran in 2020? Yes, we can do that too. And, we can do it within hours, if not minutes. It’s one thing to collect the data but it’s another to be able to use it, understand it so that it will ultimately benefit our customer.

Our Commitment

Apex Spring & Stamping has always been committed to providing the best in quality parts. We continue to make investments in the best team, testing equipment, and training or our team members. Our Apex quality philosophy has never changed: provide our customers with exceptional service and value through continuous improvement of the quality management system. We won’t let you down.

How Can We Help?

We would love the opportunity to work with you. Request a Quote or Contact us to learn more about our quality standards and process!

| Contact Us | Request A Quote |