In manufacturing and assembly, the smallest components sometimes play the biggest roles. One example of this is the compression limiter. A simple yet indispensable device designed to preserve the integrity and functionality of assemblies. Whether in automotive, aerospace, industrial, or any other application, compression limiters ensure that bolted joints maintain their performance under stress, vibration, and thermal cycling.

This following dives into the most common types of compression limiters and an alternative design we recommend that is more cost effective.

Compression Limiter Defined:

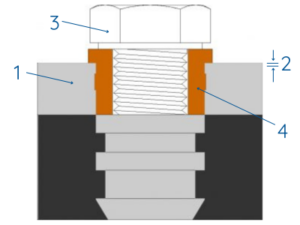

What is a compression limiter? A device designed to ensure bolted joints maintain their performance. Specifically, customers request compression limiters to line a plastic hole and prevent the plastic from splitting when a bolt is turned and torqued down. A visual picture of this is a helpful illustration. See the diagram below.

1 = component that is usually made of plastic.

2 = Amount of compression the plastic takes as…

3= the bolt is torqued to a specific torque.

4 = the compression limiter

Examples of Compression Limiters:

Compression limiters can be designed in many different ways completely depending on the application. Our team is experienced and skilled to help our customers determine the best solution for their application. Below are a few examples of compression limiters.

|

|

|

| Solid Threaded Manufacturing Method: machining |

Solid Draw Form Manufacturing Method: Progressive Die |

Split Ring Manufacturing Method: 4-Slide/Multi-Slide |

Compression Limiters at Apex

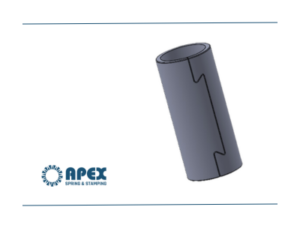

We can manufacture any of the above limiters, but we are fans of the split right compression limiters. In fact, over the years, we have seen many applications where the OEMs request a #1 solid core compression limiter only to discover that a split ring compression limiter is effective and less expensive. The tooling is less expensive and it can be easily run on a 4-slide/multi-slide machine. Also, during the manufacturing process there is little to no wasted material.

Additional advantages of a Split Ring Compression Limiter (SRCL)

- Minimal Tooling (cut off and form tools with post)

- Minimized scrap since the width of the material is the width of the part

- Maximized Speed where they can run up to 5,000 per hour (reduced Pc price)

- Alternative Materials for different torque settings on bolts

- Ease of Assembly: press fit into a chamfered hole

- Ease of adjustment of gap by variation of the feed length on the machine

Apex specializes in split-ring compression limiters. We have expanded our line of progressive die (draw forms) and ventured into alternative designs like the one shown here. We can help with tolerance stack-ups and the compression needed to make these work.

We can help with your next project!

| Contact Us | Request A Quote |