What Are Assemblies?

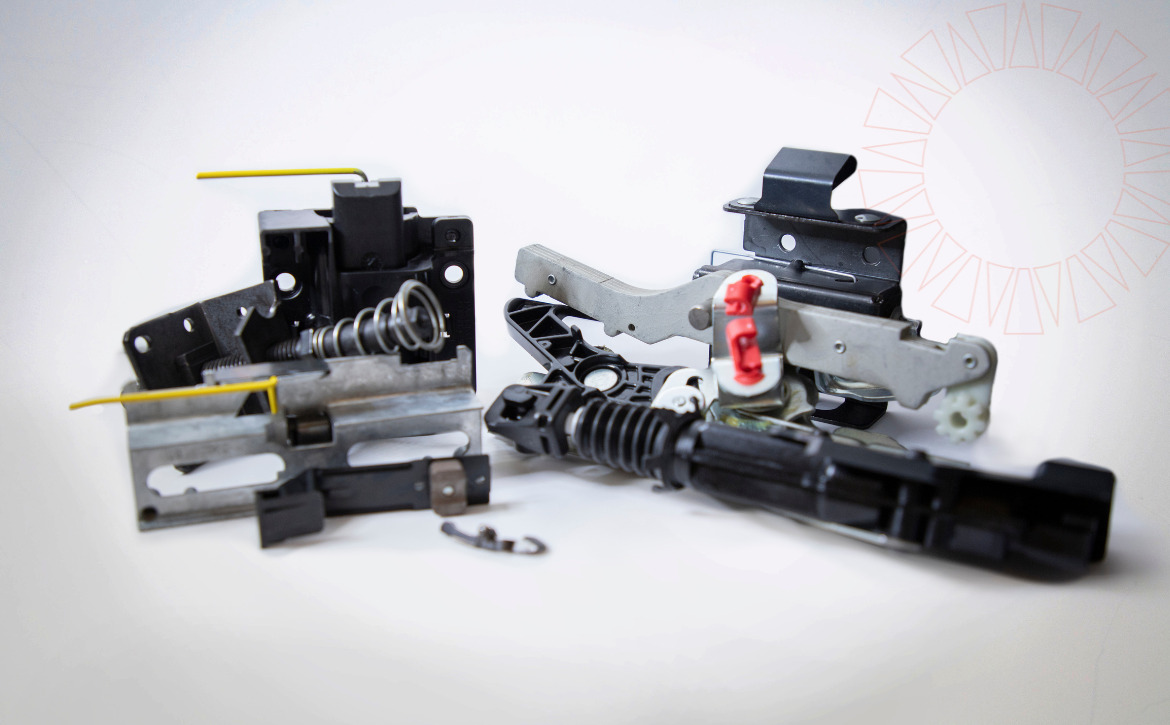

In manufacturing, the connecting or integrating of multiple components is a function we refer to as assembly. These assemblies go on to be used in the final construction of a complete and functional product. A crucial part of the manufacturing process, Apex is a leader in assembly with an entire facility and team fully dedicated to the service.

Assemblies can range from simple to complex, depending on the product. They can involve mechanical connections, fasteners, welding, adhesives, or other component joining methods. They may also include electrical/electronic components, wiring, or other specialized elements, depending on the nature of the product.

When assembling products, the goal is always to create a finished product that meets the required specifications, functionality, and quality standards. Therefore, the process often involves careful planning, sequencing of steps, and quality control measures. Occasionally it may require the utilization of specialized equipment or tools to ensure efficient and accurate assembly.

Apex has years of experience with assemblies, and we are committed to providing the highest in quality and value.

Contact Us

Assembly with Apex

Outsourcing your assembly project to Apex can be a strategic move to free your valuable resources from time-consuming tasks. Our expertise in assembly services allows us to efficiently handle all aspects of the project, from initial planning to final execution. By entrusting your assembly needs to us, you can redirect your focus and resources toward core business activities. We understand that efficiency and cost management are crucial elements for the success of any project. Our team of professionals possesses the necessary skills and knowledge to streamline the assembly workflow, eliminating inefficiencies and ensuring a smooth production cycle.

Contact us today to talk more about partnering with Apex for assembly services. From selecting the right components and materials to implementing quality control measures, we handle every aspect of the assembly process with precision and attention to detail. Contact Us or Request A Quote today!

Key Assembly Processes and Equipment

In effort to share more about how we approach assembly at Apex. The following describes equipment, capabilities, and processes we use in our assembly facility. Although we are problem solvers and we adapt when needed! So, we are always changing, growing, and adding equipment and capabilities to serve our customers’ needs.

Test Equipment

Test equipment is an essential component of our assembly process at Apex. This includes a wide range of electrical and mechanical testing tools that allow us to evaluate the quality and functionality of assembled products. Electrical testing equipment helps us assess circuitry, voltage levels, and signal integrity to ensure proper functionality. Mechanical testing equipment allows us to test strength, durability, and tolerance, ensuring that the final assembly meets rigorous quality standards. With our advanced test equipment, we can identify and address any issues or defects early on, guaranteeing that the assembled products perform reliably and meet customer specifications.

Torque Guns

Torque guns are invaluable tools used in assembly processes at Apex. These handheld devices are specifically designed to apply precise amounts of torque to fasteners, such as screws, bolts, and nuts. They ensure accurate and consistent fastening, preventing under-tightening or over-tightening of the fasteners. Maintaining the correct torque ensures secure and reliable connections, avoiding issues like stripped threads, component misalignment, or premature failure. With our skilled technicians proficient in using torque guns, we ensure that assemblies are tightly fastened, enhancing structural integrity and overall product quality.

Orbit Riveter

At Apex, we utilize the orbit riveter as a key assembly process. This specialized machine is designed to fasten components together using rivets. The orbit riveter creates an orbital motion, allowing the rivet to be set with precision and consistency. By employing this efficient tool, we can quickly and effectively join parts, ensuring strong and secure connections. The orbit riveter’s precise rivet placement enhances the assembly’s structural integrity, resulting in reliable and durable products.

Tube Cutter

Tube cutting is an important assembly capability at Apex, particularly in the plumbing, HVAC, and automotive industries. Our tube-cutting process involves using advanced equipment to achieve accurate and clean cuts in various types of tubes. This ensures precise lengths and smooth edges, enabling seamless integration during assembly. The precise cuts achieved through our tube-cutting capabilities minimize material waste and eliminate the need for additional modifications, saving time and reducing costs in the assembly process.

Welder

Welding is a crucial assembly process at Apex for joining metal components securely. Our skilled welders utilize advanced welding techniques, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and spot welding, to create strong and durable welds. Welding involves applying heat and pressure to fuse metal components, resulting in robust connections. By leveraging our welding capabilities, we ensure that assembled products have excellent structural integrity, withstand demanding conditions, and exhibit long-lasting performance. Our welding expertise allows us to handle various welding requirements, from thin sheets to thick structural components, meeting the highest standards of quality and reliability.

Automatic Greasing Machine

Apex employs automatic greasing machines as part of our assembly capabilities. These machines play a vital role in lubricating assemblies with moving parts. By utilizing precise and automated processes, our automatic greasing machines ensure consistent and optimal distribution of lubricants. This minimizes friction, reduces wear and tear, and enhances the overall performance and longevity of the assembled products. With automated greasing, we eliminate the risk of human error and achieve reliable lubrication that meets the specific requirements of each assembly. This capability not only improves the efficiency of assembly processes but also reduces maintenance needs and enhances the reliability of the final product.

O-Ring Insulation

O-ring insulation is an important process in assembly at Apex, especially for sealing applications. O-rings are essential for creating effective seals and preventing leakage in various assemblies. Our specialized insulation techniques ensure accurate placement and secure integration of O-rings within the assembly. Proper insulation of O-rings prevents contamination, maintains sealing integrity, and ensures optimal performance of the assembled product. By expertly insulating O-rings, we deliver assemblies that meet stringent quality standards and offer reliable sealing solutions across different industries.

Kitting Machine

Our kitting machine capability enables the efficient organization and packaging of components for each assembly project at Apex. This process involves systematically grouping and labeling the required components, ensuring they are readily available during assembly. By streamlining the component retrieval process, our kitting machine reduces setup time, minimizes errors, and enhances assembly efficiency. This capability allows our team to focus on the assembly, improving productivity and ensuring a smooth workflow. With our efficient kitting process, we optimize assembly operations, reduce delays, and deliver high-quality products to our customers.

Hand Assembly

While automation has transformed assembly processes, certain tasks require meticulous manual handling. At Apex, we excel in hand assembly, particularly when it involves delicate or intricate components. Our skilled technicians employ their expertise and attention to detail to ensure precise integration and alignment of components. Hand assembly allows us to achieve an optimal fit, functionality, and quality in assemblies where automated processes may not be suitable. By combining the human touch with our technical capabilities, we deliver assemblies that meet the highest standards of craftsmanship and performance.

Multiple Presses – 4, 8, 10, 12, and 45 Tons

Our assembly capabilities include multiple presses with varying capacities, including 4, 8, 10, 12, and 45 tons. Presses are versatile tools used for various assembly operations, such as inserting bearings, pressing components together, or forming specific shapes. The selection of the appropriate press ensures the application of the right amount of force for each assembly task. Our multiple presses can efficiently handle assemblies of different sizes and complexities, achieving accurate and reliable results. This capability allows us to precisely execute assembly operations, ensuring proper fits, secure connections, and efficient production processes

Request a Quote

Partner with Apex

While the key assembly processes and capabilities discussed above provide a glimpse into our expertise at Apex, it’s important to note that we continuously strive to expand our capabilities and stay at the forefront of industry advancements. At Apex, we embrace opportunities that challenge us to explore new applications and technologies. Our dedicated team is always ready to adapt and acquire the necessary knowledge and equipment to meet the unique needs of our customers. Whether it’s a simple or complex assembly requirement, we are committed to providing innovative solutions and exceeding expectations. As we progress, Apex remains driven by a passion for excellence and a relentless pursuit of continuous improvement in assembly processes and capabilities.

Get the conversation started today!

| Contact Us | Request A Quote |