Metal Stamping At Apex

Metal stamping, it’s an integral part of manufacturing today. But, there are many facets to metal stamping. With a wide range of capabilities, machines, materials used, etc., it leaves lots of room for questions. Therefore, we put together some of our most frequently asked questions about metal stamping here at Apex. We would love the opportunity to be part of your next project. Reach out today and lets talk.

Request A QuoteWhat are the types of metal stamping processes?

Metal stamping techniques are divided into three categories:

- Progressive Dies

- Four-slide Tooling

- Multi-slide Tooling

What are the advantages of Metal Stamping?

Stamping has a number of advantages over other more labor-intensive techniques, such as:

- Reduced die costs

- Elimination of secondary costs

- Reduced costs

What is the stamping process in manufacturing?

Stamping is an industrial manufacturing technique for transforming flat metal sheets into desired finished shapes. A continuous coil of steel is fed through a stamping press, where the metal is formed into a final shape by a tool and die surface.

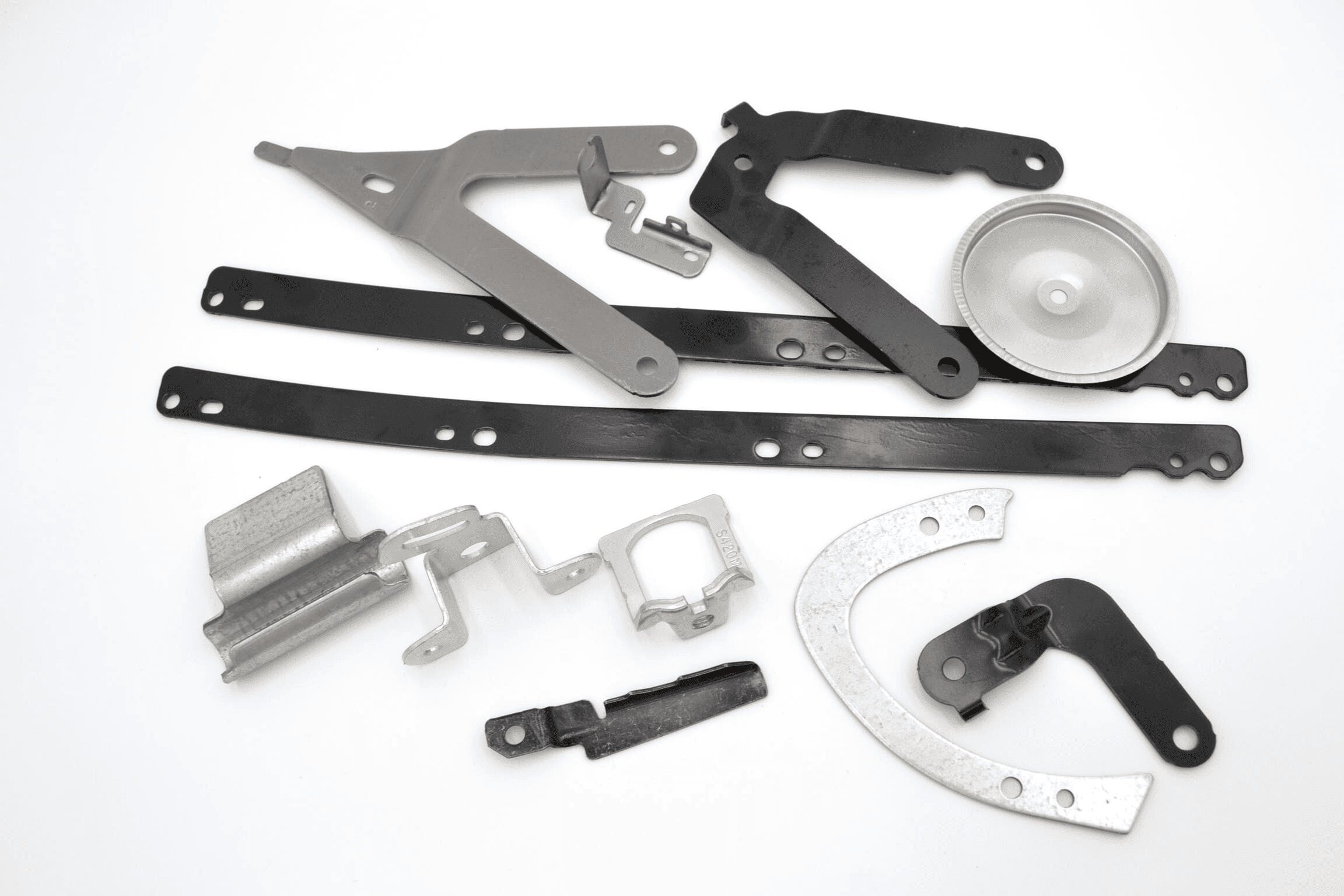

What products does Apex make for their customers currently?

- Brackets

- Hinge Plates

- Stop Tabs

- Compression Limiters

- Fasteners

- Speed Nuts

- Tinner type clips

- Automotive Center Console Parts

- Horn Brackets

- Wall System Brackets

- Motion Control Brackets

- Components for lighting and lamps

- Products for decorative stamping

- Components of bearings

- Automobile components

- Controls and components for appliances

What are the production capabilities of the press equipment?

Apex Spring and Stamping provides equipment with the following production capacities:

- (20) 45 – 250-ton gap frame presses

- Press bed sizes range from 16.0” x 31.5” (45 ton) to 34.0” x 106.0” (250

- ton)

- In die sensing (standard on all tools)

- Inline (die) tapping – reduced processes/handling

- In die staking – reduced processes/handling

- Customer-specific designs

- Low to high volume run capabilities

- Material Thickness: .010″ – .250″

- Material Width: .079″ – 18.0″

We Can Help

Apex is dedicated to manufacturing high quality parts, and building lasting and trustworthy relationships with our customers. Contact us or request a quote today to start a conversation and learn more about partnership opportunity.

| Contact Us | Request A Quote |