Why Prototype?

A prototype provides specifications for a real, working system rather than a theoretical one. By definition, a prototype is an early sample, model, or pre-release of a product built to test a concept or process. So, why is it valuable? Well, developing pre-production parts serves as proof of concept. It also makes sure a part is feasible to manufacture and feasible to produce. A well-thought design will fit the category of these things:

- Cost Effective Manufacturing Process

- Ease of assembly

- Ease of Tooling

- Reduction in Tooling changes and costs to change hard tooling

- Reduction in scrap by optimization of blank or material

Who Should Prototype & Where To Go?

Many OEM companies go to prototype shops to help develop a part for their products. Unfortunately, many of those shops have no interest in whether or not the part is feasible to manufacture (DFM = design for manufacturing). They have no concept or experience in developing a production process. So, they make the parts as is, and you are stuck with the development that is not manufacturable. This is why it is wise to use a production house, like Apex Spring and Stamping. Our strong development team provides engineering services to develop a cost-effective sample that is easy to manufacture.

When to Prototype

The best time to do prototypes is when you are in the design and development stage of any project. Often, the spring product is overlooked. We may need to fit the overstressed part into a tight space, and if not properly developed, we are typically set up for design failure. Doing a prototype can avoid this failure.

NOTE: The most important thing to ask a spring designer: How much space do you need to make this design a success?

A Story of Prototype Success

Apex is always pleased when prototyping leads to success for our customers. A great example is a story about one of our customers who was developing a consumer product. They came to us with the complex stamped metal part. They invited us into the development stage, and we worked for 6 months to develop a cap and base for a personal hygiene product. Early development resulted in a reduction in tooling changes and the feasibility of forming the correct material for the correct application.

The following describes many of the elements that contributed to the development of this unique consumer product.

Material Selection

The material selection was critical for this product. A stainless steel was selected based on its ability to polish, and keep from rusting in a very tough environment. This was a consumer product that was exposed to harsh chemicals and moisture with a high susceptibility to rust in a bathroom environment. Also, this product needs to be portable in backpacks, purses, or utility bags.

Initial Scanning and 3d Printing in Plastic

This was critical to development. We took three dimensional CAD Data and made it into a touch-and-feel product. Shown above are…

- 3d printed part for touch and feel samples

- Draw Tooling sample before cut-off development on the lip.

- Tumbling example for cut-off development

Polishing example for mirror finish

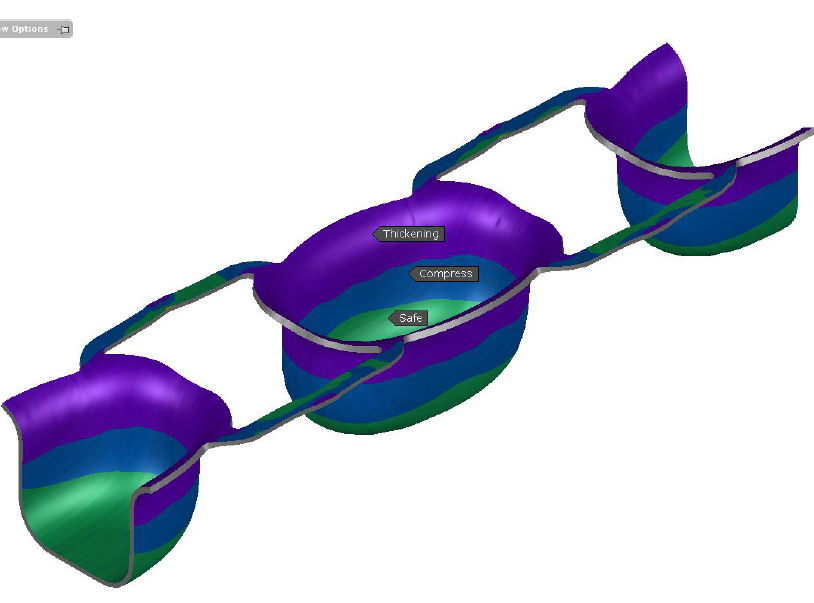

Forming Simulation and Tooling Design

When the final material was selected, the biggest question was: can we draw a 300-400 series stainless steel to the depth needed for the design of this product?

To answer this question, the thinning and thickness of steel were simulated in software that Apex has access to in their tool room. Apex can simulate how the metal will flow very accurately before an actual part is ever manufactured. This simulation also helped with the development of the prototype tooling. Shown below is an image from the simulation software.

Development from the forming simulation was critical for the production and cost of the part. Simulations help with making the best of the strip utilization, for costing.

Special Cut-Off Development

Also for this product, the cut-off burr was not acceptable. It required there be no sharp edges. Therefore, the development of the cut-off was critical to the success of the product.

The four areas that were attacked were the:

- Cut-Off Process

- The Tumbling Process

- The Coating Process

- The Polishing Process

This all helped with the final edge of the part.

Finish

Also critical to the functionality and look of the product was powder coating and masking.

When used the cap and base mated with plastic internal parts. So, the sizing (with the coating) is important. The required size was determined by the force a user would require in order to open and close the product. Therefore, special consideration was used for the process and tolerance stack up for the final product success.

Polishing & The Finished Product

The bottom of the unit was a separate draw form and the dimensional and finish were also critical for the product. Therefore, we developed some polishing systems to make the stainless steel very highly polished. It was also a reusable option for reducing the amount of plastic in landfills.

This is an image of the finished product. Our team and the customer were very pleased with it. It exceeded expectations in quality and was delivered on time. And, prototyping was a critical step in the journey to success for this customer and this product. What projects are you working on right now that could benefit from a prototype? Contact us or Request a Quote today!

| Contact Us | Request A Quote |