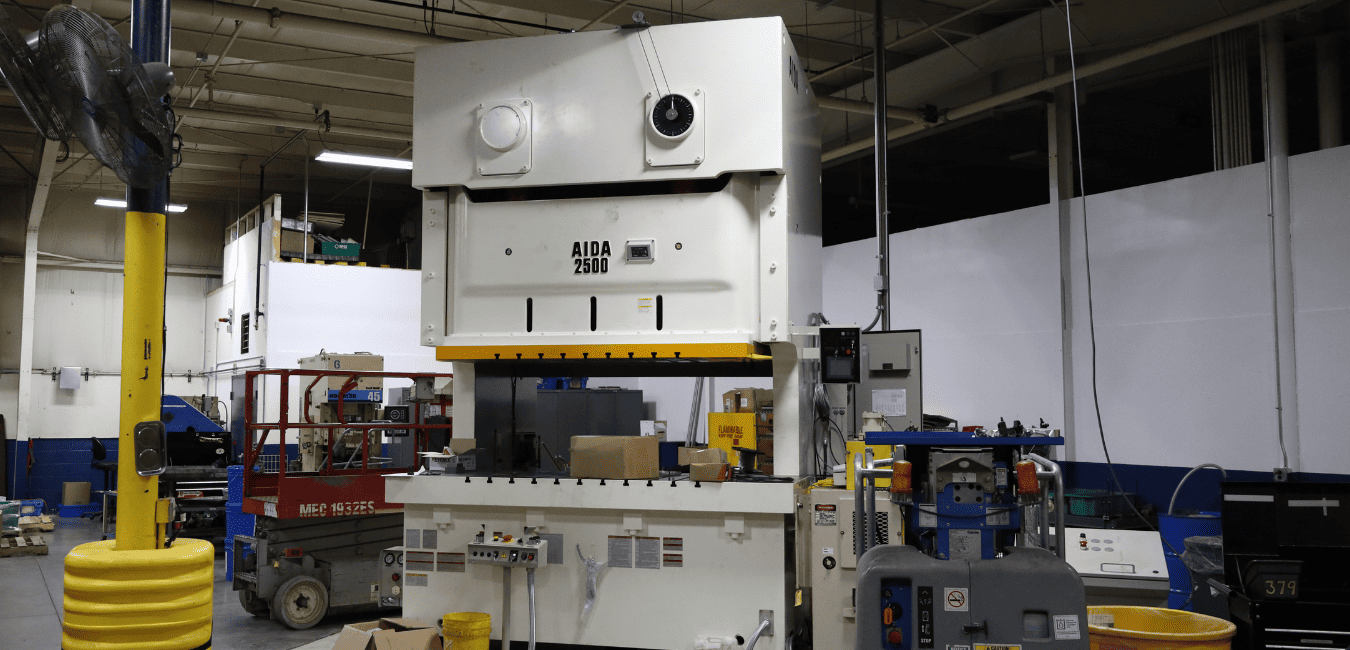

Introducing Our Largest Press

Our team makes every effort to continue to adapt to meet the needs of our customers. That’s what commitment and strong relationships look like. A recent area of growth is in our press department. In 2023 we added to our team a brand new 250 ton press (made by AIDI). We’re still pretty excited about this addition and we thought you might be too.

How This Changes Things

In previous years, our team began to recognize the need and opportunity to expand our metal stamping capabilities with a bigger press. So, once we decided on the machine and where it would be located, we started demolition on the plant floor. It was necessary to pour a new 18” concrete slab to support it’s weight. After all, it weighs approximately 72,000 lbs. It also features a 106” bolster. That’s almost double the size of our bolster on the next largest press. Obviously this larger bed allows us to take on larger more complex parts that require larger dies with more stations. Additionally, this means more capabilities and efficiencies.

We Are Here to Help

We’d love to share more with you about our new capabilities and how the new press changes things for us and our customers. Projects we may not have been able to do in the past, are now possible. Therefore, whatever you have coming up in the future, we’d love to help. Get the conversation started by Requesting A Quote or Contacting Us today.

| Contact Us | Request A Quote |