What material should I use?

As a spring manufacturer, we always get asked to become an integral part of the decision-making process on what material to use in the specific application. Here are some questions you need to ask about the use and application of the part.

- Is the part being used as a spring (cyclical)?

- Is the spring under high stress? Higher stress higher carbon….

- Is the part being welded? Less carbon…

- Is corrosion a problem?

- What type of corrosion will the part see and what is the salt spray requirement?

- Is the operating temperature higher than normal?

- Is the spring involved with carrying electricity?

- Does the spring need to be round or flat?

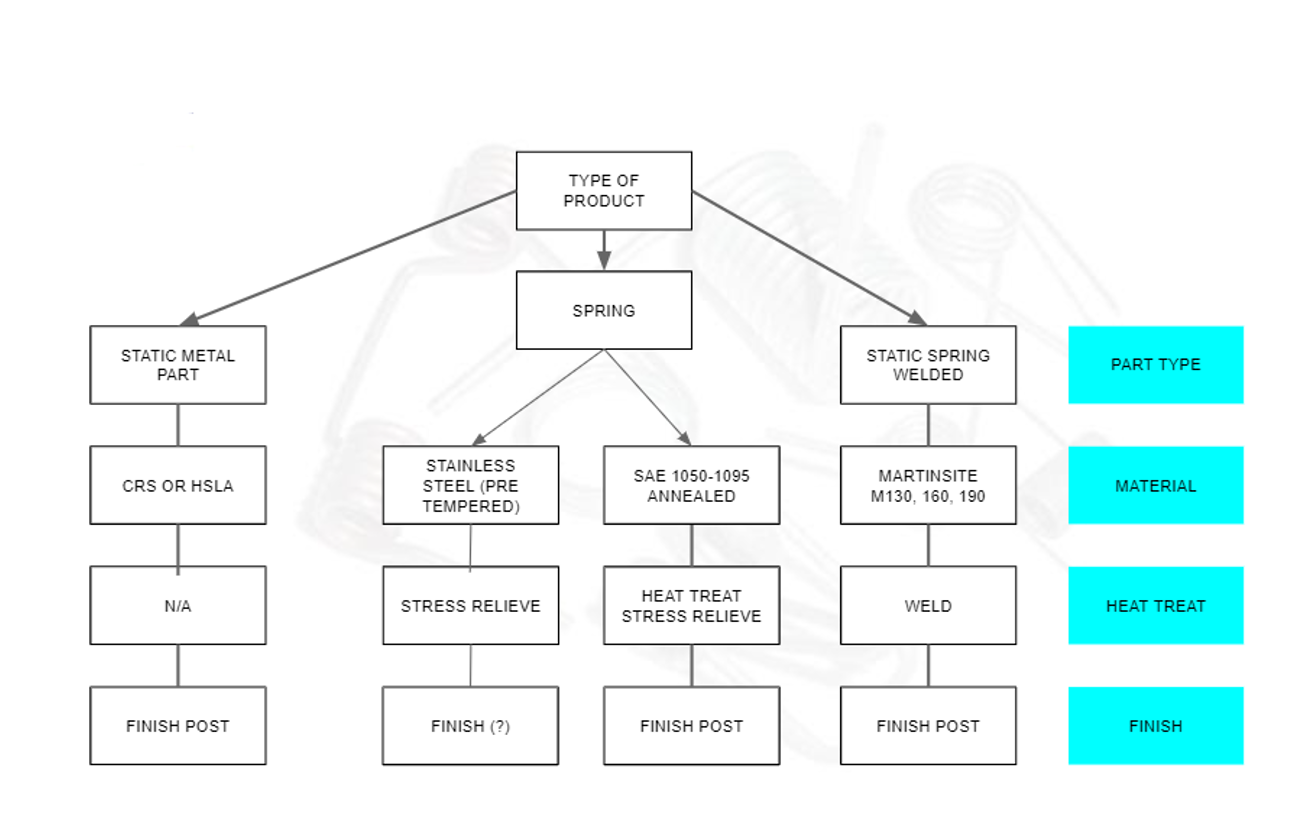

Here is a simple matrix to help you decide on what direction you want to go with Material. This is a simple matrix but let us help with what your application is trying to do. Clipping, clamping, moving, holding, static, cyclical twisting, compressing, and extending, you name is we can help!

We have many types of materials, carbon content, and heat treating, and finishes that can be applied to all the above questions. Why ask so many questions? Because we want to get it right, the first time. We want to provide you with the most economical part that will function above and beyond your requirements.

That’s the Apex difference. How Can We Help?

| Contact Us | Request A Quote |