Tom Little, Sales

APEX Spring & Stamping

With the help of CAD, spring designers are making simple and complex components for a variety of products. The cost of simple designs has been driven up as designers lose touch with the ability to make simple parts simple.

The cost of springs has several factors. When making a spring you can assume that 30-50% of the total product cost is for materials. Another major cost factor is the number of bends and the tolerance tightness per spring. For each bend of the spring, a machine is required to slow down and increase dwell time, which increases cost.

The chart below shows commonly manufactured spring types compared to costs and mating complexity.

Common Springs: Cost vs. Mating Complexity |

|||

| Spring Type | Cost Range | Mating Complexity | Mating Description |

| Compression | $ | High | Requires mating hold or pin to keep in place |

| Torsion | $$ | Medium-Low | Requires mating pin and surfaces for legs to connect |

| Extension | $$$ | Low | Two pins or holes

to hook legs into |

| Wire Forming | $$ | High | Requires complex interaction with mating parts |

| Double Torsion Spring | $$$$ | Medium-Low | Mating in and three mating component surfaces |

*This chart is generalized and does not factor in materials, tolerancing, or other potential factors.

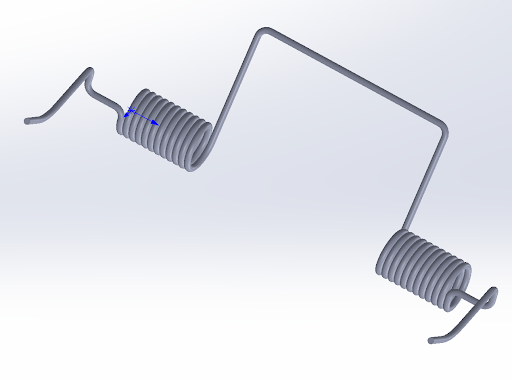

High Cost Design Example

Double torsion springs (shown to the left) typically run very slowly on machines due to bends on both sides of the spring and the tight tolerances. In addition, these springs are difficult to use during assembly, and overall require heavy consideration for use. All of these factors lead to a higher cost.

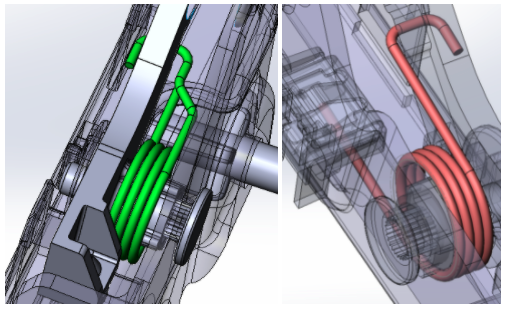

Cost Savings Redesign

On the left you can see the initial design (green) was across the coil of the body, and two additional bends were needed for the manufacturing of the part. The Apex Spring & Stamping Team redesigned this (red) into the opposite wind spring, and reduced cost by eliminating bends. Remember, bends add time to the manufacturing process, and cost additional dwell time on the machine, thus raising the price.

The Apex Spring & Stamping Team works with companies of all sizes to design springs that save money and headaches. We believe a little creative thinking, technology, and decades of experience can go a long way to find a cost-effective solution. Let us help you design the perfect spring.

| Contact Us | Request A Quote |