Kim Dykman, Purchasing/Supplier Development

APEX Spring & Stamping

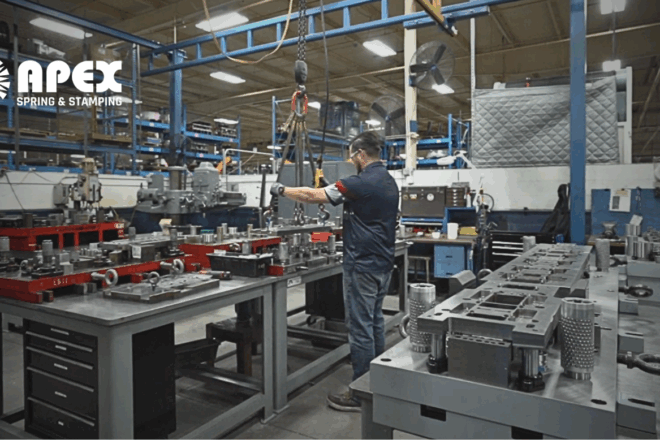

Apex expands Headquarters

The past two years have been challenging to say the least. People and businesses around the globe have faced a myriad of obstacles from every direction. With ever-increasing prices, material, and labor shortages, we find ourselves asking, “Why would anyone spend more money to prepare for business growth and not just try to maintain current sales?”

At Apex Spring & Stamping, we put the customer and their needs first. In the midst of the COVID-19 Pandemic, senior management decided the time was right to prepare for the post-pandemic market and add on to our main building. The Apex team is always looking for new and better ways to serve our current customers and attract new ones.

In the summer of 2021, Apex broke ground to add additional 5,000 square feet to their main manufacturing facility. The extra space allows for new equipment that will open opportunities to expand product lines and to add more space for raw material storage. Both of these areas are pivotal for customer success, but amidst global supply chain issues, Apex needed additional space to store raw material to ensure that they had resources available to run parts and meet schedules.

Construction is complete and the move-in process was completed at the end of 2021. This expansion has not only increased floor space, but it has also made our shop more efficient with the bonus of a clean and bright environment. We have been able to maintain our “on-time delivery” scores, control inventory, stage material for our tight schedules while materials keep arriving on our docks. Our capacity to make quick changes and respond to our customers has allowed us to keep our competitive edge.

Team Apex will continue to plan ahead and make bold decisions, even during this unprecedented business climate.

Can we help with your next project?

| Contact Us | Request A Quote |