Happy Anniversary!

On our 45 anniversary we’re sharing the story of Apex’s journey from 1976 through 2022.

1976

It was the holiday season in 1976 when Wayne Nash, married with two young children, found himself unemployed. After several sleepless nights with no business plan or financial support, he decided to create his own job. Wayne had past experience with fourslide equipment in manufacturing so he naturally focused on what he knew.

When asked about his humble beginnings 45 years ago, Wayne describes the business as a chain with many links. Each chain link at Apex has the same strength and importance to the company’s success. Wayne Nash, founder of Apex Spring and Stamping will tell you, “the Lord brought us to where we are by blessing us with strong links from the very beginning.”

Wayne’s previous coworkers and business relationships formed the first two links on the Apex chain. A previous coworker, also unemployed, came to Wayne and offered to work for no pay for a period until the business could afford to pay him. One of Wayne’s business relationships from years prior had a fourslide sitting in his backroom. He offered the fourslide to Wayne to get started. This same contact provided the tooling and raw material for Wayne to run his first parts.

With a small team and equipment in place, the next challenge was to find space to run the large machine and begin manufacturing. Wayne rented an oversized garage in the Standale, MI area; the landlord offered to forgo rent for a few months until Wayne could get things moving. Yet another answer to prayer.

After securing a machine, a team, and space the first parts came out of Apex. Wayne hand-delivered parts to a local, large appliance manufacturer. Wayne was able to show his first potential customer what he could do, how well he could do it and the cost savings he could provide. Those first parts impressed them and more orders soon followed.

Wayne will tell you that he had no special contacts or reputation in the world of manufacturing to support his efforts. It was all the work of the Lord putting those first links in the chain together.

1980’s

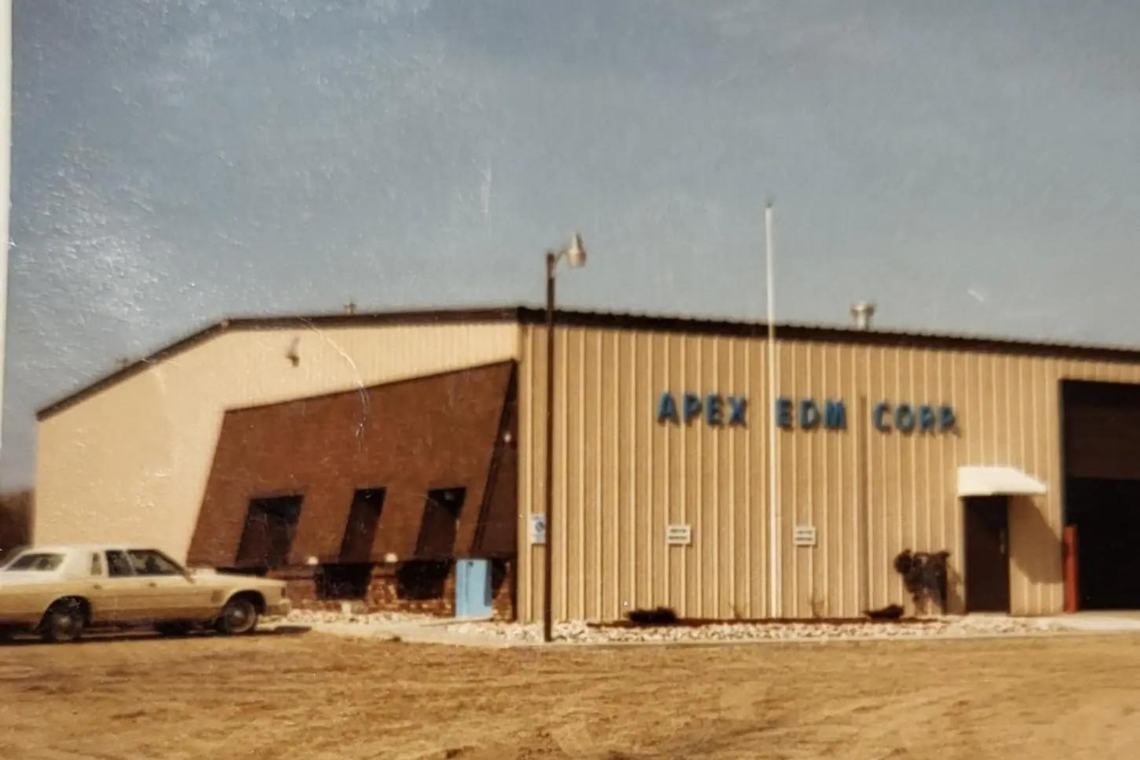

In the early 1980s, Wayne and the team outgrew the rental garage and moved to a larger facility on Lake Michigan Drive in Allendale, MI. With a handful of employees and a few fourslide machines, they began taking on more customers. With the success of providing high-quality parts at an affordable price for nearly 17 years, Apex purchased its first stamping press.

Soon after the purchase of the stamping press, a gentleman presented his wire spring work to Wayne and the team. After that presentation Apex hired another link and added torsion machines to the product mix. The chain continued to grow, adding more team members and equipment.

1990-2019

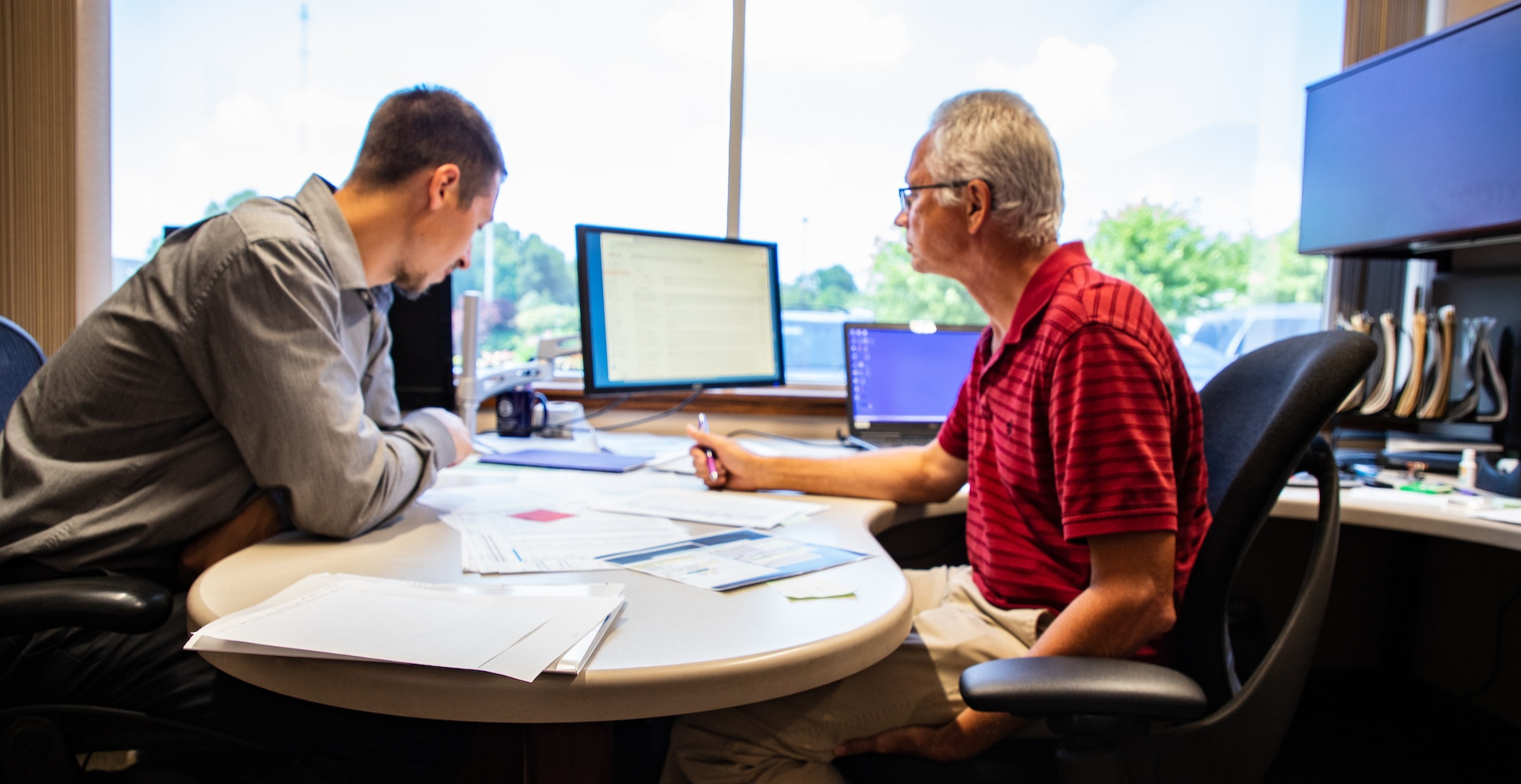

In 1994, with 10 employees and one million dollars in sales Wayne hired the company’s CPA, Dennis Bhaskaran. Dennis came on board to help grow the company. 1994 was a very important year in Apex’s history because it was the same year that Apex became the first spring company in Michigan to achieve ISO-9000 registration. This is a large accomplishment for a very small company.

In 1999 thanks to the hard work of the Apex team, a brand new building was constructed in Tallmadge Township’s Industrial Park in Michigan. The building was originally 48,000 square feet, but in 2007 Apex added another 30,000 square feet to the building, moved employee parking, and added a solar farm across the street.

Wayne retired and enjoys sitting back and watching his son, Ben Nash, who came on board in 2012, and Dennis as they continue to add links to the chain.

Apex continued to grow under the leadership of Dennis and Ben and in 2019 built a 43,000 square foot warehouse next to the solar farm along with more docks to avoid truck congestion at the main building. Apex customers can pick up parts and Apex can ship orders without traffic backup. A third facility was added in Howard City, MI dedicated to value-added processes and assembly.

2020+

Throughout the next 22 months, Apex worked tirelessly to make the needed changes to continue providing the same extraordinary care it had provided for the past 43 years. Excuses were never an option. The success and longevity of Apex are because of the ‘Continuous Improvement Program’ that rewards team members quarterly for their time and cost savings ideas.

Apex values low employee turnover, excellent benefits, and the latest technology. The “ready to serve attitude” allowed Apex to keep recurring customers and attract new ones. Each employee and customer is met with a sparkling clean, brightly lit, and friendly work environment. To quote Dennis Bhaskaran, Apex’s President, “The Company is in a great position for the future to continue the tradition of our family and Christian values to lead Apex into the opportunities ahead.”

Celebrating 45 years of business in January of 2022 Apex expanded again adding an additional 5,000 square feet to max out the original facility. Much of the growth has been done to prepare for customer needs and to provide more services and value.

Today, Apex’s manufacturing space includes 15 fourslides, a dozen presses of various sizes, and over 60 torsion machines and wire benders. The company now has a workforce of over 70 people and three locations. Apex Spring & Stamping supplies a variety of parts to not only the appliance industry but also automotive, office furniture, recreational vehicles, electric vehicles, retail displays, and much more.

Apex prides itself on being a full-service supplier from engineering and design support, prototyping, tooling, and production to assembly and kitting projects. The philosophy at Apex Spring and Stamping has remained the same throughout the past 45 years, “We walk the talk. It starts from executive management all the way down; no one person or link is any better than another or too good to do any task at the company.”

Here’s to the next 45 years!