Apex is Your Assembly Solution

Free up your valuable resources by outsourcing your assembly project to Apex. We are highly experienced and skilled in handing all aspect from start to finish.

Manufacturers are looking for help to relieve the pressures of keeping production moving effectively and efficiently. They are also continually looking for ways to improve efficiency and manage costs. Assembly at Apex can help! Here are three reasons to consider outsourcing your assembly needs to the team at Apex!

Reasons to Outsource Assembly

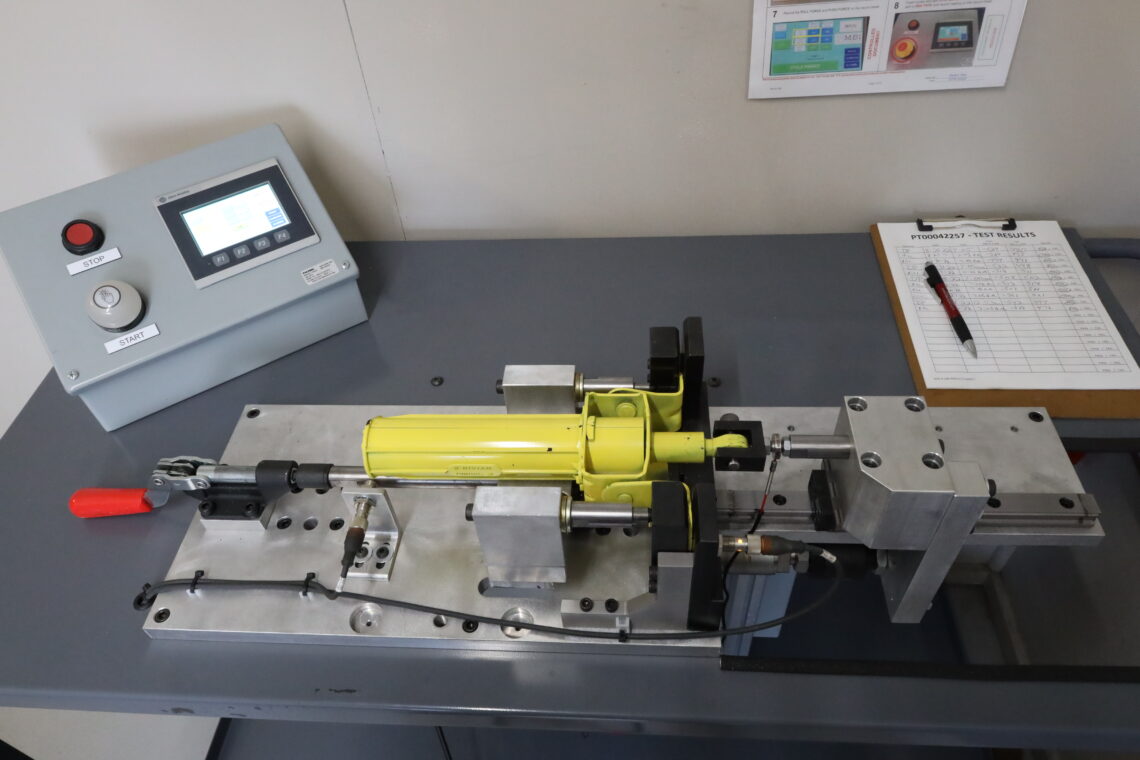

Assembly at Apex allows companies to outsource their projects to our talented team and top of the line facilities to get the job done. Saving them time and money.

Here are the three major reasons we’ve found our customers are choosing to partner with Apex for assembly:

#1. Save Labor Costs

It’s all about labor. Hiring is often not an easy task. There is not a shortage of work, but there is a shortage of laborers. That’s where working with experienced partner like Apex has its perks. Our team is already in place. We can easily take the work, allowing you to utilize your team for their core competencies. Our qualified assembly team is trained on proven procedures that ensure your product is assembled correctly, quickly.

#2. Inventory Management

Apex has also been able to significantly reduce the amount of time our customers spend tracking, managing and coordinating components for a finished product. Why? Because we do it for them! Our facility has designated areas called ‘cells.” This ensures special projects are handled so you don’t have to manage and keep track of every part. We manage the project from start to finish, including your inventory.

#3. Reducing Risk

More good news, when working with Apex, we absorb the responsibilities and risk. Parts that don’t arrive on time? The Apex team is on it. Defective parts due to assembly issues? Apex will handle it. You get the peace of mind that you will receive a finished product or part that meets your quality requirements.

Can Apex Help your team?

Cost savings, flexibility, access to expertise, risk management and efficiency are all benefits of outsourcing assembly! Apex is experienced and well equipped to provide these benefit for your manufacturing. With our entire facility and staff dedicated just to assembly, we can customize processes depending on our customers needs. If that means new equipment or labor, we make it happen. So lets chat about your assembly needs, we want to help!

| Contact Us | Request A Quote |